Key Advice for Starting and Scaling an Electronics Manufacturing Business

- Amos Faulkner

- Oct 29, 2025

- 4 min read

Entering the electronics manufacturing industry requires a sharp mix of strategic foresight, operational discipline, and adaptability. Entrepreneurs who succeed here understand that building hardware isn’t just about circuits and solder, it’s about precision, partnerships, and continuous improvement.

This article explores practical insights to help new founders navigate production, supply chains, and scalability in a fast-changing global landscape.

So, to thrive in electronics manufacturing:

● Start with clear market validation and quality benchmarks

● Design for manufacturability and scalability early

● Build strong supplier relationships and resilient logistics

● Leverage automation and modern control systems to enhance productivity

● Prioritize safety, compliance, and sustainable innovation

Understanding the Landscape

Electronics manufacturing demands more than innovation. It requires operational excellence. From semiconductor components to consumer devices, entrepreneurs must align their product vision with reliable production capabilities. Learning platforms like MIT OpenCourseWare and resources from the Electronics Manufacturing Association can offer valuable foundational insights.

Core Advice for New Entrepreneurs

The Foundational Checklist

Before launching a manufacturing venture, confirm these essentials:

✅ Market Clarity — Identify your niche (industrial, consumer, IoT, etc.) and validate real demand

✅ Financial Readiness — Secure funding that supports tooling, testing, and compliance costs

✅ Supplier Network — Build partnerships with reliable component and PCB vendors

✅ Regulatory Compliance — Prepare for UL, CE, or ISO standards early to avoid costly redesigns

✅ Prototype Discipline — Start lean, iterate fast, and document every production step

A structured guide such as Nerd Wallet's Startup Finance Overview can help refine capital strategies.

How to Build Efficient Manufacturing Processes

Step-by-Step:

Design for Manufacturability (DFM): Simplify assembly, reduce part counts, and ensure component accessibility

Adopt Lean Principles: Minimize waste, optimize workflows, and integrate continuous feedback loops

Invest in Quality Systems: Use statistical process control and regular audits to maintain consistency

Automate Wisely: Apply automation where it adds measurable value without overextending capital

Monitor Supply Chain Risks: Implement visibility tools to anticipate delays or component shortages

For a deeper understanding of global supply systems, explore Inbound Logistics

Enhancing Production Through Automation and Control

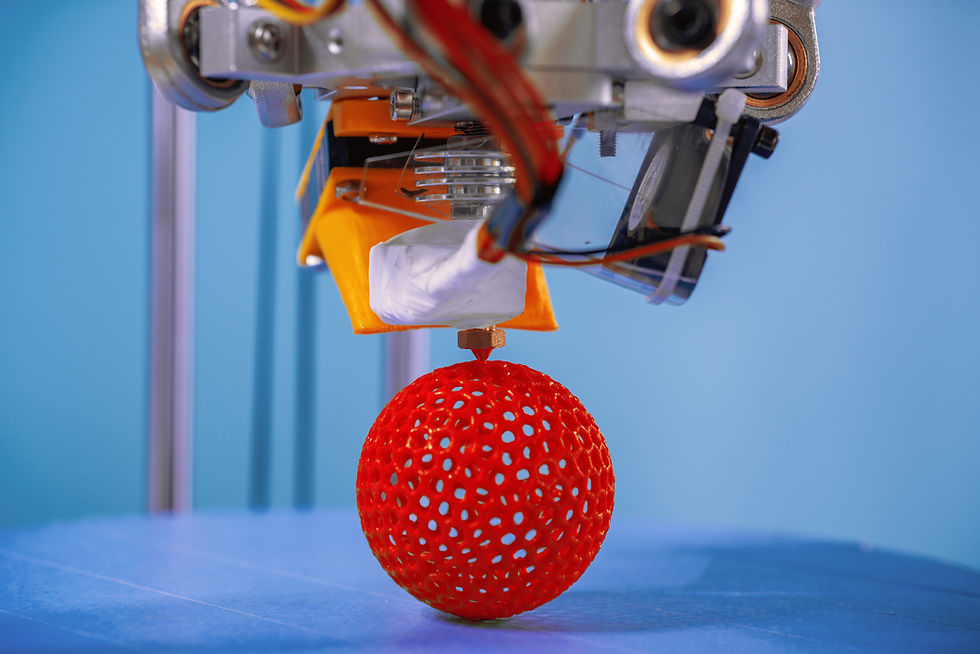

Modern electronics manufacturing increasingly depends on precise automation and control frameworks that reduce human error and maximize throughput. Entrepreneurs can integrate automation and control solutions to synchronize sensors, conveyors, and inspection systems for higher yield and lower waste.

Investing in a hardware platform built for real-time precision, seamless integration, and global deployment helps unify operations across facilities. Such systems empower growth and enable smarter data-driven decisions. To learn more about scalable industrial solutions for automation and control you may consider this resource.

Flex, a global electronics manufacturer, uses advanced automation to streamline PCB assembly through to final system testing. By integrating machine vision and AI-powered defect detection, they’ve cut scrap rates and boosted uptime. Startups can look to Notion, a smart sensor company that scaled after crowdfunding by deploying modular test rigs and cost-effective automation. Their approach shows how smaller ventures can use smart systems to move efficiently from prototype to production, without sacrificing quality or stretching limited resources.

Building Your Brand and Market Presence

Even with exceptional engineering, visibility matters. Effective marketing separates successful manufacturers from those that remain hidden in supply chains.

Partnering with specialized marketing strategists at The Marketing Jack can help refine your story, build credibility, and connect with your ideal partners. Combine digital targeting with trade show presence, public relations, and technical storytelling to stand out.

Navigating Challenges and Growth

Common Roadblocks

● Rising component costs and shortages

● Quality drift during scaling

● Overreliance on a single supplier or distributor

● Talent shortages in precision manufacturing

Solutions

● Diversify suppliers across regions

● Train teams through Coursera’s Industrial Automation Specialization

● Adopt transparent metrics and production dashboards

● Reinvest in R&D for sustainability and efficiency

Leveraging Smart Design Tools

Entrepreneurs who use tools like Autodesk Fusion 360 or KiCad early in development often reduce time-to-market significantly. These design ecosystems improve collaboration and manufacturability checks before production begins

Stages of Manufacturing Maturity

Stage | Focus Area | Core Actions | Key Metrics |

Startup | Validation | Prototype, market test | Cost per prototype |

Growth | Optimization | Automate & scale | Yield %, defect rate |

Expansion | Diversification | Add suppliers, optimize costs | Production uptime |

Maturity | Sustainability | Innovate, reinvest | Efficiency ratio, ESG compliance |

Glossary

● DFM (Design for Manufacturability): Designing products for efficient and cost-effective production.

● Yield: The percentage of products meeting quality standards.

● Supply Chain Resilience: The ability to adapt and recover from disruptions.

● Throughput: Total production output in a defined time frame.

● ESG: Environmental, Social, and Governance - sustainability performance metrics.

Product Spotlight: Streamlined Project Management for Manufacturers

Managing complex electronics production cycles often means juggling multiple timelines and vendors. Tools like Monday.com offer an easy-to-adopt project management system that helps teams coordinate procurement, testing, and delivery without losing oversight ideal for startups building process discipline.

Conclusion

Aspiring entrepreneurs in electronics manufacturing face steep challenges, but success comes from preparation, adaptability, and focus on process excellence. By integrating automation, fostering supplier trust, and mastering marketing and operations, new ventures can transform from garage prototypes into global players, built on innovation, efficiency, and resilience.

About the Author

Amos Faulkner wants to help people “do money well.” Money is a constant in our lives. Yet, as a bank teller, Amos realized that many people don’t pay enough attention to how much they have or how much they need, now and in the future. Well, now, the buck stops with his site, domoneywell.com. From teaching your children how to manage their money to saving for your golden years, Amos will cover it all

Elevate your business with The Marketing Jack and tap into expert advice that turns insights into effective marketing strategies. Stay ahead of the competition by exploring our well-researched blogs and proven projects for unmatched success.

Comments